Top 10 Injection Molding Companies in India

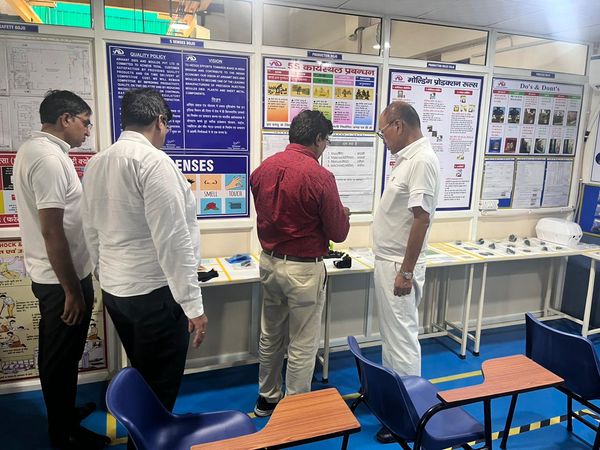

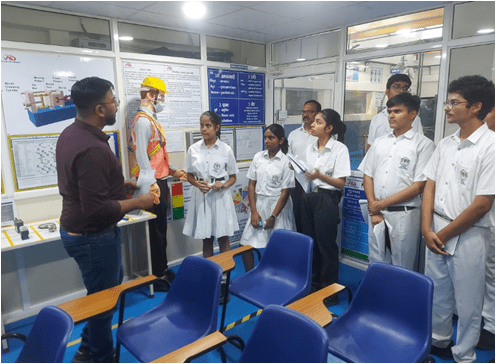

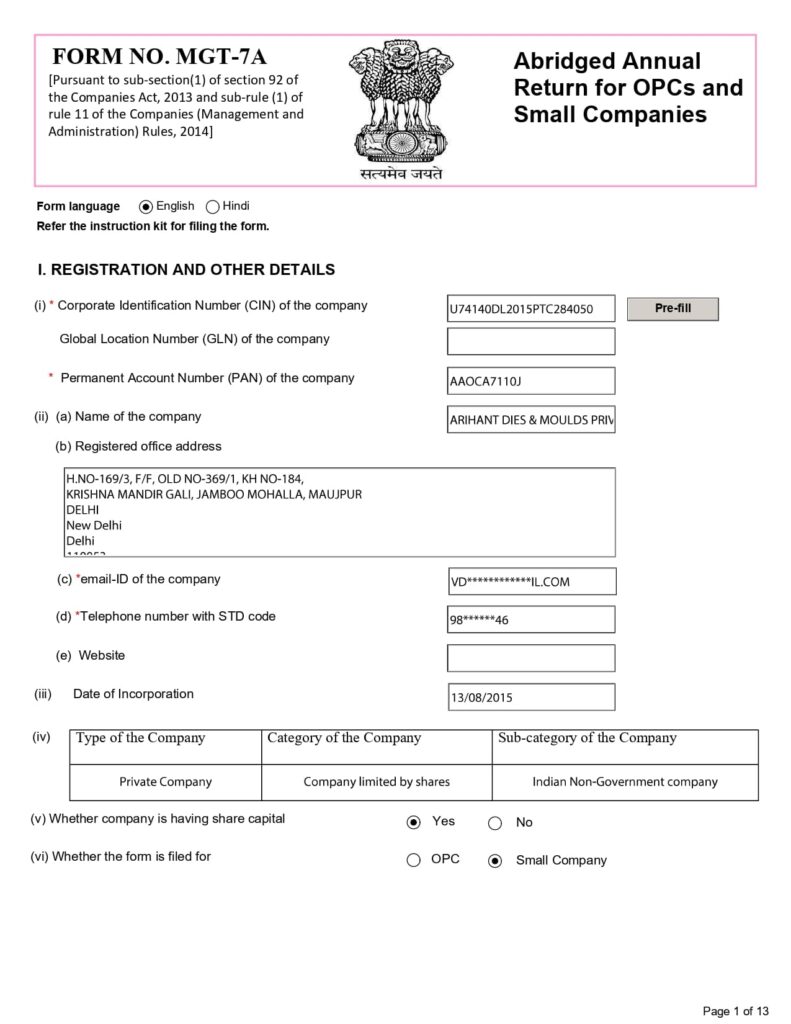

Plastic products are one of the most ubiquitous items found around the globe due to their light weight, durability and affordability. Market trends state that in India, being one of the top growing economies, there has been a significant demand for high-quality, complex plastic products across industries and domestic needs as well. As the demand for plastics has increased, so has the innovation and advancement in its manufacturing, and injection molding is one such technology that is enabling the growth of the plastic product market. Injection molding is an efficient process of mass manufacturing identical parts of a particular product by injecting molten plastic into a mold cavity and cooled to solidify it, giving it the desired size and shape. Using this advanced method of mechanical engineering, many companies have emerged to provide plastic injection molding services in India. The accuracy and precision of injection moulding are highly essential attributes of this process because it prevents the wastage of plastics. Top 10 Injection Molding Companies Injection moulding is a highly sophisticated process that demands expertise, robust infrastructure and high-yield machines. So, while many companies are emerging in this field, not all can give the best output. Therefore, choosing from the top list of injection moulding companies is a prudent decision. If you are someone looking to get a credible list of top names in this domain, this is exactly the blog you need to read. here is the list of the top 10 Plastic Injection Molding companies in India: Arihant Dies & Moulds Pvt Ltd Dalal Plastics Pvt Ltd Think 3D Supreme Industries Ltd Anantha Naayaki Industries Micro Plastics Pvt Ltd Thanusar Enterprises Polymech Plast Tooling Temple General Plastic Industries LLP #1. Arihant Dies & Moulds Pvt Ltd Location: Ghaziabad, Uttar Pradesh Founded in: 2015 Main Products: Injection Molds, Injection Molded Parts for Automotive, Electrical, Home Appliances, Insert Molds. Arihant Dies and Moulds Pvt Ltd is the fastest-growing Injection molding company In India. The company specializes in injection molding solutions providing excellent quality molded parts in the automotive industry, electrical appliances, and for domestic use. The key driver of their success is incorporating integrated solutions, through which they remarkably reduce cost, and human error, ensure accuracy, and maintain stable supply chain systems and quality standards. Equipped with state-of-the-art machines, their manufacturing unit is unparalleled and has well-compartmentalized teams who are specialized in their specific domain and skilled enough to collaborate to produce the best outcome. To assure high performance and safety, they run stringent quality and safety tests before dispatching to the customers. Whether you need hot runner mold auto unscrewing mold, their experts and latest machinery can carry out all kinds complex projects within the stipulated time. These molds for injection guarantee zero downtime and are available in a versatile range of 80-250 tones of clamping force. All of these factors assimilate together to make them the most trusted brand in the list of best injection molding companies. #2. Dalal Plastics Pvt Ltd Dalal Plastics Pvt Ltd was founded in 1968, therefore they have a lot of experience in this domain. Through their wide experience, Dalal Plastics Pvt Ltd has established a reputed name in the plastic injection molding industry. Their key services include plastic injection molding, tooling, subassembly, welding, etc. #3. Think 3D Think 3D is reliable for mitigating delays and cost-overrunning challenges in the manufacturing industries. Located in Hyderabad, they are a renowned provider of digital manufacturing services which includes plastic molding, CNC machining, 3D printing and 3D scanning. Serving various industries like automotive, textile, electronic, aviation, defense, etc., they have an in-house facility equipped with cutting-edge machinery and dedicated professionals to design and produce plastic injection molds of varying types. #4. Supreme Industries Ltd Supreme is one of the largest plastic products manufacturers in the country. The company’s history spans over 80 years, showing its wide experience in the domain. Their injection-molded products are widely used in automotive, and by OEMs. #5. Anantha Naayaki Industries Anantha Naayaki Industries is a Chennai-based company specializing in all kinds of precision moulding designing and machining. They cater to a wide number of clients in the automotive, aviation, electrical and furniture-making industries. With robust designing software and expert technicians, they stand on their commitment to providing the best services and therefore a trusted name in the list of top manufacturers of plastic injection molds. #6. Micro Plastics Pvt Ltd Micro Plastics Private Limited is a Bangalore-based manufacturer founded in the year 2005. They are one of the leading manufacturers of injection molds and tools for several industries. To keep quality in check and up to high standards, they have advanced technology and skilled professionals. They are known for providing reliable, precise and high-performance plastic molds. #7. Thanusar Enterprises Thanusar Enterprises is a trusted manufacturer of injection molds catering to automotive industries, electronics, domestic use and thermoformed plastic products. With around 3 decades of experience, they have been successful in offering high-quality injection molds at low cost. The company assures quality as they are ISO-9001:2015 certified. #8. Polymech Plast As a trusted manufacturer, supplier and service provider of plastic molds, Polymech Plast lay the most emphasis on customer satisfaction. They have an innovative product manufacturing system through which they provide plastic molding solutions to clients across India. Their dedication combined with cutting-edge machinery makes them a key player in India’s top 10 plastic injection mold manufacturers list. #9. Tooling Temple Tooling Temple is a prominent company known for manufacturing high-quality injection molds in versatile shapes and precise designs. The industries they serve are automotive, electrical, defence, aviation, electronic parts and textile. Using advanced machines and software like Solid Works, Toolmaker, Electrode etc., they ensure the best quality, performance and precision of the designed mold. #10. General Plastic Industries LLP Established in 1968, General Plastic Industries LLP is an end-to-end provider of plastic injection molded solutions to various industries. They have gained immense expertise in close-tolerance functional parts.