Dojo of Dreams: Transforming Learning at Arihant Dies & Moulds

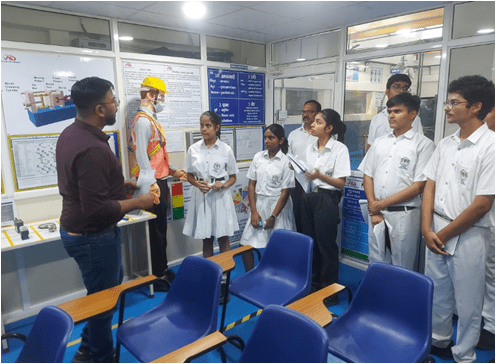

In a landmark moment, Arihant Dies & Moulds inaugurated its Corporate with their precious Client & Mentor Mr. Rajeev Gandotra (Executive Director & CEO of UNO Minda) leading the ceremony. More than a room, this space represents a revolutionary approach to employee development, blending technological innovation with holistic learning philosophy. The state-of-the-art facility offers skill enhancement zones, digital learning platforms, and wellness areas. Mr. Gandotra emphasized that manufacturing excellence stems from developing human potential. The dojo symbolizes our commitment to continuous improvement, integrating technical training, leadership development, and personal growth. A testament to our vision of empowering employees through knowledge and innovation.